DHP 4.0 Axial Piston Pump - 4.0m³/h High-Pressure Water Treatment Consumables for Medium-Flow Desalination

Подробная информация о продукте:

| Место происхождения: | Китай |

| Фирменное наименование: | Fenigal |

| Сертификация: | CE |

| Номер модели: | DHP 4.5 |

Оплата и доставка Условия:

| Количество мин заказа: | 1 шт |

|---|---|

| Цена: | обсуждаемый |

| Упаковывая детали: | Стандартная экспортная упаковка |

| Поставка способности: | 60000 единиц в месяц |

|

Подробная информация |

|||

| Модель продукта: | DHP 4.0 | Геометрическое смещение: | 32 см=/Прев |

|---|---|---|---|

| Рейтинг поток при номинальной скорости (1800 об / мин): | 4,0 м³/ч (эквивалентно 73,3 л/мин. При минимальном расходе) | Минимальное давление в выходе: | 20 бар |

| Максимальное непрерывное давление выхода: | 80 бар (для требований более высокого или более низкого давления, пожалуйста, свяжитесь с торговым п | ||

| Выделить: | DHP 4.0 axial piston pump,high-pressure water treatment consumables,medium-flow desalination pump |

||

Характер продукции

Core Advantages for Water Treatment

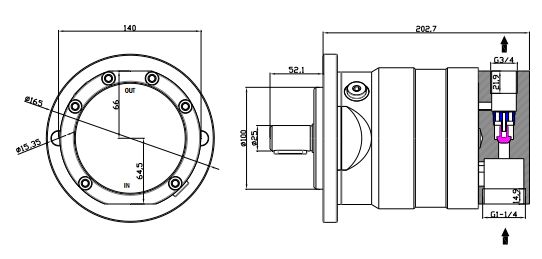

Core Technical Parameters of DHP 4.0

Power Parameters (1800 rpm Rated Speed)

Inlet & Outlet Dimensions

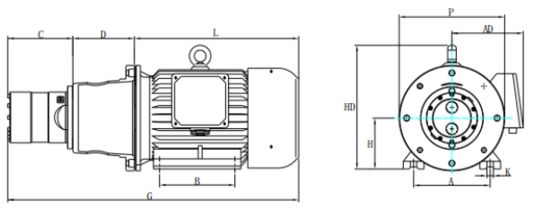

Overall Dimensions (mm, with Motor)

Installation & Operation Tips

Maintenance & Warranty

Manufacturer Information

![]()

Хотите узнать больше подробностей об этом продукте