DHP 2.7 Аксиально-поршневой насос (2,7 м³/ч, 80 бар) – Расходные материалы для водоподготовки высокого давления для опреснения

Подробная информация о продукте:

| Место происхождения: | Китай |

| Фирменное наименование: | Fenigal |

| Сертификация: | CE |

| Номер модели: | DHP 2,7 |

Оплата и доставка Условия:

| Количество мин заказа: | 1 шт |

|---|---|

| Цена: | обсуждаемый |

| Упаковывая детали: | Стандартная экспортная упаковка |

| Поставка способности: | 60000 единиц в месяц |

|

Подробная информация |

|||

| Модель продукта: | DHP 2,7 | Геометрическое смещение: | 15 смЧ нетерпением/Rev |

|---|---|---|---|

| Рейтинг потока при номинальной скорости (3000 об / мин): | 2,7 м³/ч (преобразовано в 45 л/мин. При минимальном расходе) | Минимальное давление в выходе: | 20 бар |

| Максимальное непрерывное давление выхода: | 80 бар | Минимальное давление входа: | 1 бар |

| Максимальное непрерывное давление на входе: | 5 АДВОКАТУР | Непрерывный ряд скорости: | 700 ~ 3450 об / мин |

| Выделить: | high-pressure axial piston pump,water treatment consumables for desalination,2.7m³/h axial piston pump |

||

Характер продукции

Основные технические параметры DHP 2.7

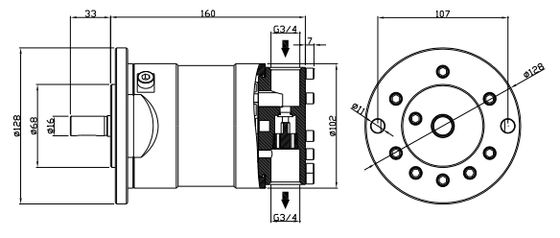

Размеры входа и выхода DHP 2.7

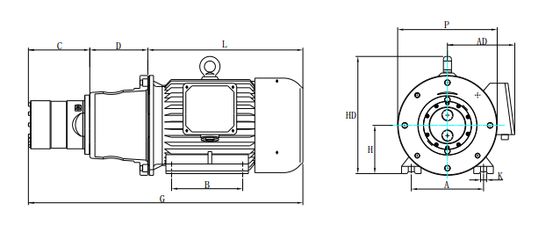

Габаритные размеры DHP 2.7 (Единица измерения: мм)

Контактная информация производителя

![]()

Хотите узнать больше подробностей об этом продукте