DuPont AmberLite HPR4200 Cl Ионобменная смола для деминерализации промышленных вод с целыми неразбитыми шариками ≥ 90% и опухолью 20%

Подробная информация о продукте:

| Место происхождения: | КИТАЙ |

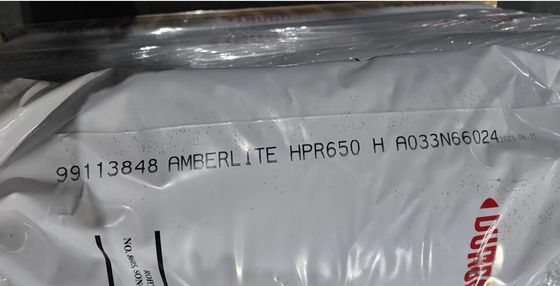

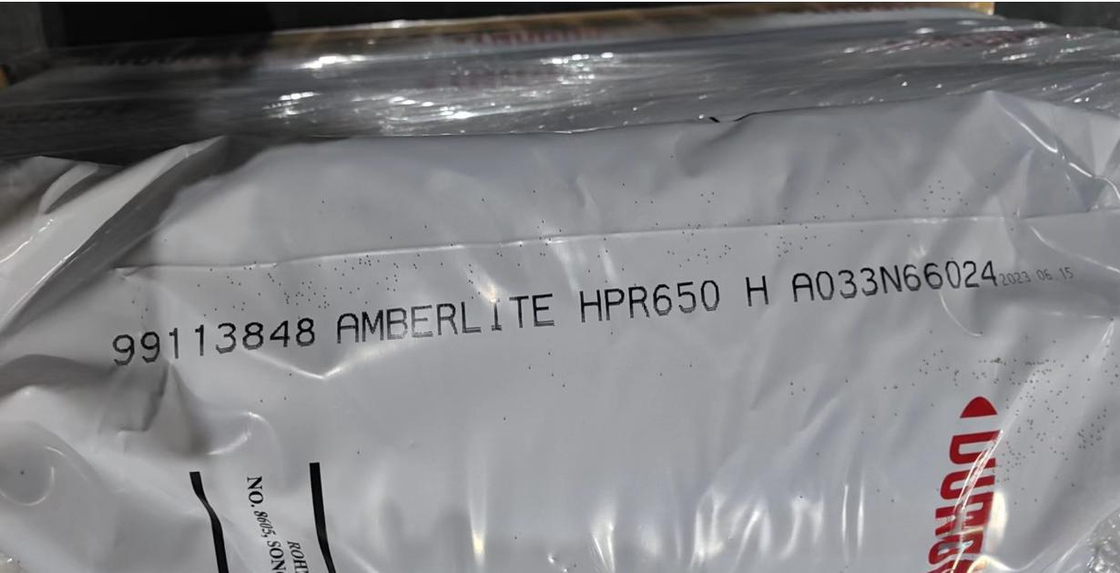

| Фирменное наименование: | Dupont |

| Сертификация: | ISO9001 |

| Номер модели: | Dupont ™ Amberlite ™ HPR4200 CL |

| Документ: | IER-AmberLite-HPR4200-Cl-PD...en.pdf |

Оплата и доставка Условия:

| Количество мин заказа: | 1 шт |

|---|---|

| Цена: | обсуждаемый |

| Упаковывая детали: | Стандартная экспортная упаковка |

| Время доставки: | 5-8 рабочих дней |

| Условия оплаты: | T/T. |

| Поставка способности: | 60000 единиц в месяц |

|

Подробная информация |

|||

| Основные области применения HPR4200 CL: | Промышленное деминерализация воды | HPR4200 CL Цельные нетреснутые шарики: | ≥ 90% |

|---|---|---|---|

| HPR4200 CL Набухание (Cl⁻ → OH⁻): | 20% | HPR4200 CL Плотность частиц: | 1,07 г/мл |

| Предупреждение HPR4200 CL: | Сильные окислительные агенты (например, азотная кислота) могут разрушить смолу или вызывать насильст | Физическая форма HPR4200 CL: | Желтые полупрозрачные сферические бусы |

| Тип: | Сильный базовый анион, тип I | ||

| Выделить: | Целые неразбитые шарики ионно-обменная смола,Отек 20% AmberLite HPR4200 Cl,Плотность частиц 1 |

||

Характер продукции

DuPontTM AmberLiteTM HPR4200 Cl Ионно-обменная смола для деминерализации промышленной воды

DuPontTM AmberLiteTM HPR4200 Cl - это высококачественная гелевая смола с однородным размером частиц и сильной основой типа I, предназначенная для промышленной деминерализации воды.Он поставляется в виде хлорида (Cl−).

Обзор продукции

Эта смола предназначена для обеспечения высокой работоспособности и низкого падения давления, что способствует снижению потребления химических веществ во время регенерации и снижению потребности в воде для промывки,предлагает экономически эффективную эксплуатациюЕго сбалансированные химические и физические свойства делают его универсальным и высокопроизводительным выбором для различных систем очистки воды.

Заявления

- Деминерализация

- Идеально подходит для обработки воды с высоким содержанием кремнезема

- Эффективен для удаления сильных и слабых кислот и достижения низкой утечки кремния

- Смешанное полирование кровати

Совместимые конструкции систем

- Смешанные кровати

- Сборные кровати

- Полотенца на слоях

- Системы противотока / удержания

- Системы сотового тока

Рекомендуемые пары смолы

- Для смешанных кроватей:

- AmberLiteTM HPR1200 H (гель)

- AmberLiteTM HPR1300 H (гель)

- Для слоистых покрытий:

- AmberLiteTM HPR9500 (макропорный)

- AmberLiteTM HPR9600 (макропорный)

Исторические сведения

Ранее продавался какDOWEX MARATHONTM 4200 Cl Ионная смола.

Типичные свойства

Физические свойства

| Недвижимость | Спецификация |

|---|---|

| Сополимер | Стирен-дивинилбензол |

| Матрица | Гель |

| Тип | Сильный анион основы, тип I |

| Функциональная группа | Триметиламоний |

| Физическая форма | Желтые полупрозрачные сферические бусы |

Химические свойства

| Недвижимость | Спецификация |

|---|---|

| Ионная форма (как отправлена) | Cl− |

| Общая обменная способность | ≥ 1,30 eq/L (в форме Cl−) |

| Водосдерживание | 490,0 - 55,0% (в форме КЛ−) |

Распределение размеров частиц

| Параметр | Спецификация |

|---|---|

| Диаметр частицы | 650 ± 50 мкм |

| Коэффициент единообразия | ≤ 1.25 |

| < 300 мкм | ≤ 0,3% |

| > 850 мкм | ≤ 5,0% |

Дополнительная информация о размерах частиц приведена в документе No 45-D00954-en.

Стабильность

- Целые неразбитые бусины:≥ 90%

- Опухоли (Cl− -> OH−):20%

Плотность

- Плотность частиц:10,07 г/мл

- Масса на перевозке:670 г/л

Условия эксплуатации

- Диапазон температуры:

- Форма OH−:5 - 60°C (41 - 140°F) †

- Форма Cl−:5 - 100°C (41 - 212°F)

- Диапазон pH:

- Цикл обслуживания:1 - 14

- Стабильность:0 - 14

† Работа при повышенных температурах (например, > 60-70°C) может повлиять на срок службы смолы.

Гидравлические характеристики

- Расширение отмывания:Расчет расширения постели в зависимости от скорости потока и температуры обратного промывания показан на рисунке 1.

- Падение давления:Оценка падения давления в зависимости от скорости и температуры рабочего потока показана на рисунке 2 (действует для чистой воды на начало рабочего хода).

(Примечание: для графических данных см. оригинал документа.)

Безопасность и соответствие

Предупреждение:Сильные окислительные вещества (например, азотная кислота) могут разлагать смолу или вызывать сильные реакции.

Пользователям следует ознакомиться с информацией о безопасности (SDS) и обеспечить соответствие местным правилам.

Хотите узнать больше подробностей об этом продукте